Making Best Use Of Product Top Quality Through Effective Foam Control Approaches

Making Best Use Of Product Top Quality Through Effective Foam Control Approaches

Blog Article

A Comprehensive Guide to Applying Foam Control Solutions in Your Workflow

Effective foam control is an essential element of functional efficiency that commonly goes overlooked. Comprehending the complexities of foam generation can dramatically impact both performance and item quality. This guide details the different challenges positioned by foam and the varied options offered, giving a framework for selecting and applying the most ideal approaches. By checking out essential aspects such as application compatibility and employees training, organizations can maximize their foam monitoring efforts. As we discover these parts, the potential for transformative renovations in your operations comes to be evident. What actions will you take next?

Comprehending Foam Challenges

Foam challenges are a considerable concern across various industries, affecting operational effectiveness and item top quality. The formation of excessive foam can hinder processes such as mixing, transportation, and storage, causing enhanced downtime and waste. In fields like food and drink, pharmaceuticals, and petrochemicals, foam can interfere with manufacturing lines, causing product disparities and contamination threats.

Furthermore, foam can block tools performance, causing expensive fixings and upkeep. For example, in wastewater therapy, foam can interrupt clarifier operations, causing reduced therapy effectiveness and governing conformity problems.

Recognizing the underlying root causes of foam generation is critical for reliable monitoring. Factors such as surfactants, temperature changes, and anxiety degrees can all contribute to foam manufacturing. Identifying these aspects enables sectors to apply targeted approaches that lessen foam formation while keeping product honesty.

Sorts Of Foam Control Solutions

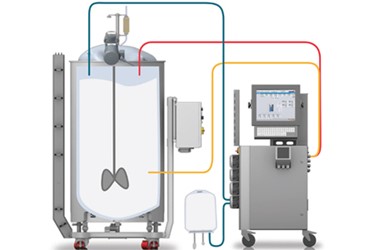

Mechanical remedies entail the usage of tools such as foam skimmers or defoamers. Chemical services, on the other hand, consist of the application of defoaming representatives-- compounds that interfere with the foam structure, leading to its collapse. Foam Control.

Last but not least, operational techniques focus on process adjustments. This might involve customizing devices parameters, such as temperature and stress, or changing the circulation rates of liquids to decrease foam generation. Moreover, applying excellent housekeeping methods can additionally reduce foam formation by minimizing impurities that add to foam stability.

Choosing the proper foam control remedy entails evaluating the details needs of the procedure, consisting of the type of procedure, the attributes of the materials included, and safety factors to consider.

Selecting the Right Products

Selecting the best foam control items calls for a comprehensive understanding of the certain application and its one-of-a-kind difficulties. Elements such as the type of foam, the environment in which it occurs, and the preferred outcome all play crucial functions in product selection. Foam Control. As an example, in industries like food handling, it is necessary to choose food-grade defoamers that abide by security guidelines while successfully handling foam.

Additionally, take into consideration the thickness of the fluid where the foam problem exists. Some products are created for low-viscosity applications, while others are tailored for thicker liquids. Compatibility with existing check this site out processes is one more crucial facet; the picked foam control representatives should integrate seamlessly important source without disrupting overall procedures.

Another essential aspect is the technique of application. Some products might require dilution, while others can be applied directly. Assessing the ease of usage and the needed dosage can give insights into the product's effectiveness and cost-effectiveness.

Application Strategies

Successful application strategies for foam control services require a systematic method that straightens product selection with functional demands. The initial action involves a detailed analysis of the processes where foam occurs, recognizing specific locations that necessitate treatment. By engaging cross-functional groups, consisting of design, production, and high quality guarantee, companies can gather understandings that educate the option of one of the most effective foam control products.

Next, it is crucial to develop clear objectives for foam reduction, making certain that these goals are quantifiable and achievable. This may involve defining acceptable foam levels and the timelines for application. Training personnel on the residential properties and application approaches of selected foam control agents is equally vital, as correct use is crucial for optimum results.

Furthermore, incorporating foam control options into existing workflows calls for careful preparation. Ultimately, a well-structured technique will certainly improve operational effectiveness while effectively taking care of foam-related challenges.

Monitoring and Evaluating Efficiency

Tracking and assessing the effectiveness of foam control solutions is essential for guaranteeing that implemented approaches generate the wanted outcomes. This process includes organized data collection and evaluation to analyze the efficiency of foam control agents and strategies. Key efficiency indications (KPIs) should be established prior to implementation, enabling for a clear standard versus which to measure progress.

Assessing performance likewise calls for routine reviews of foam control procedures and representative efficacy. This can be accomplished through tasting and testing, enabling operators to figure out if present services are fulfilling operational demands. In addition, it is vital to get comments from staff member that communicate with these systems daily, as their understandings can expose operational nuances that quantitative information may overlook.

Inevitably, a structured tracking and evaluation framework assists determine necessary modifications, making sure that foam control remedies continue to be efficient, cost-efficient, and aligned with business goals.

Verdict

Finally, efficient foam control solutions are necessary for optimizing operational effectiveness and preserving item top quality. A complete understanding of foam obstacles, integrated with the option of proper items and application strategies, facilitates the successful monitoring of foam generation. Developing measurable KPIs and spending in employees educating further boost the efficiency of foam control actions. Regular monitoring and examination make certain continual improvement, ultimately causing an extra streamlined and efficient functional setting.

Executing great housekeeping practices can also mitigate foam formation by minimizing pollutants that add to foam security.

Selecting the right foam control items needs a comprehensive understanding of the certain application and its one-of-a-kind challenges (Foam Control).Effective implementation techniques for foam control options call for an organized technique that aligns product option with functional demands.In conclusion, efficient foam control solutions are necessary for maximizing functional effectiveness and preserving item quality. A complete understanding of foam difficulties, combined with the option of ideal items and application approaches, promotes the successful administration of foam generation

Report this page